Production

Wiesner-Hager has developed into an important player in the European furniture industry. The company based in the Innviertel region currently employs 240 members of staff at its headquarters in Altheim. In the production plant, "Made in Altheim", modern manufacturing technologies are combined with a high level of employee skills.

Panel production

This winning formula makes Wiesner-Hager one of the quality leaders in the industry today. For instance, the new laser edging process for panel production, in which table tops and carcass components are manufactured, is a genuine milestone in panel design.

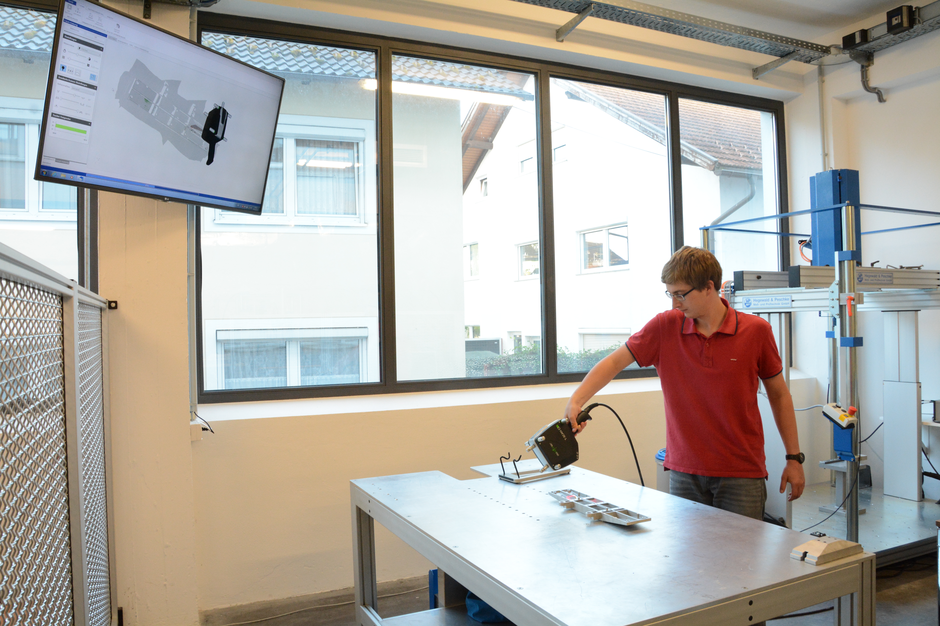

Metal production & powder coating

Modern machinery also supports the production processes in metal manufacturing to produce furniture components made of steel and aluminium. After each processing step a quality inspection is carried out by our experienced staff. In the powder coating department, metal furniture parts are painted and then sent for final assembly.

Wood processing & paint shop

In wood processing, solid wood and plywood are processed into chair frame parts and seat supports. The process consists predominantly of mechanical processing such as planing, milling, drilling, sanding and bonding. The wooden chair and table frames are then treated with water-soluble stains and water-based varnishes.

Upholstery

Upholstery has been taking place in Humpolec since the founding of the Czech subsidiary plant. While the cutting of the textiles for the upholstered elements is largely automated using a cutter, the actual sewing and upholstery work still requires a considerable amount of manual labour.

Final assembly & shipping

The final production step of our furniture takes place in the final assembly area, where our chairs, tables and carcasses are assembled according to customer specifications and prepared for shipping Wiesner-Hager operates its own vehicle fleet. After picking in the shipping department, our truck drivers and fitters transport the furniture to our customers and ensure that delivery is smooth and the furniture is securely assembled.

Inter-divisional departments such as maintenance or the electrical workshop ensure that these modern production processes run smoothly. What is more, integrated quality assurance guarantees the excellent quality of our products throughout the entire production process.